Producing Multilayered Pastry with Ultra High Production Capacity! ANKO developed an "Triple Line High Capacity Paratha Production Solution" for a Bangladeshi client

This ANKO client is a well-known food manufacturer in Bangladesh, and their business scope includes multiple food fields. They have been using semi-automatic equipment to produce Paratha to supply their domestic market demand. To expand their Paratha sales internationally, this client purchased ANKO’s fully automated food machines to produce an estimated 100,000 pieces per day in order to meet the global market demand. This ANKO return customer is confident in our high-quality machine performance and the professional support services we provide. Our team customized a Triple Line High Capacity Paratha Production Line for this company. With the assistance of ANKO’s Bangladeshi local distributors, this client visited our Taiwan headquarters to conduct trial machine operations, and the results successfully met the client’s required production requirements and food specifications.

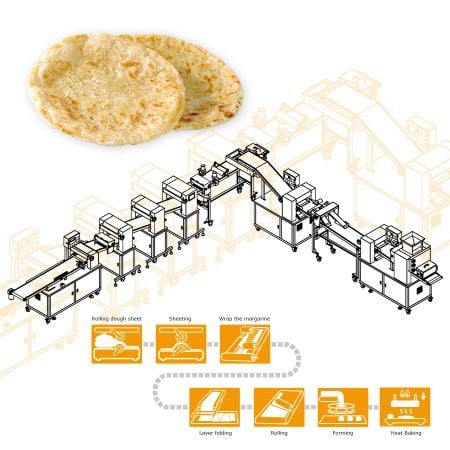

Paratha

ANKO Team Research Problem Solving or Solution Delivery

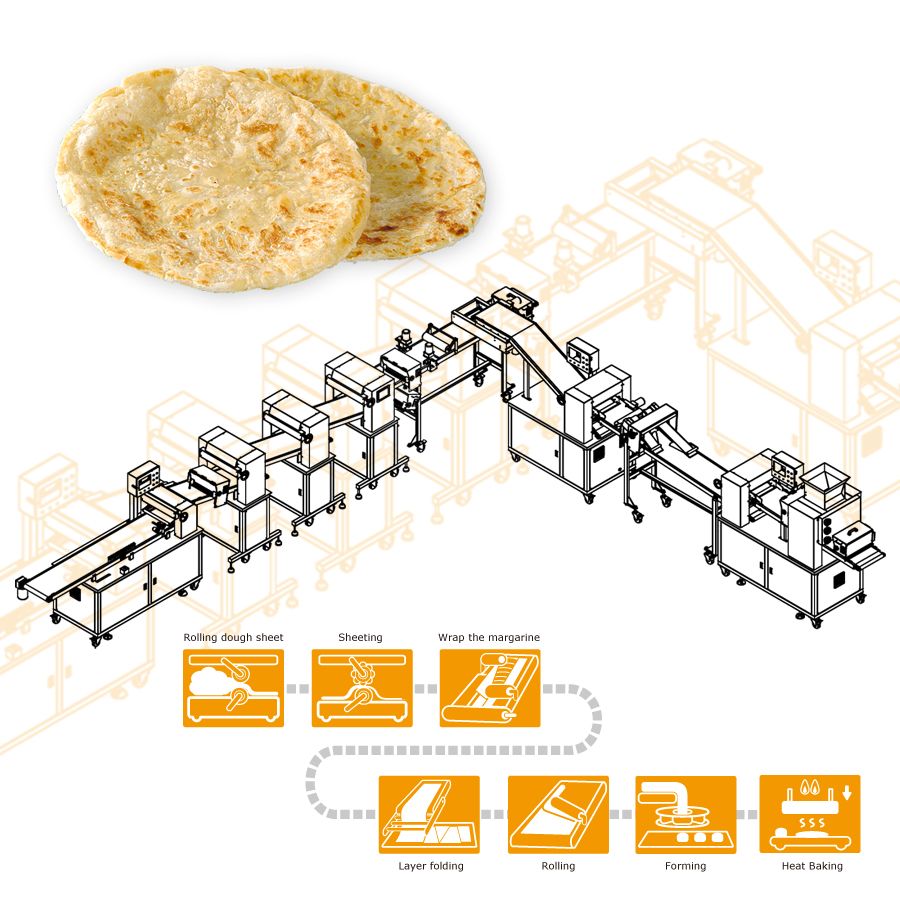

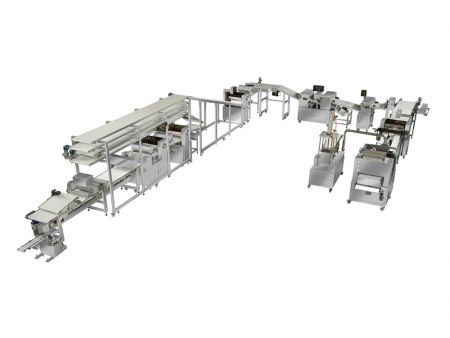

Solution 1. Customized Design – ANKO’s Triple Line High Capacity Paratha Production Line

A single Paratha production line has a production capacity of 3,000 pieces per hour; this customer required a daily production capacity of at least 100,000 Parathas. ANKO’s engineers immediately requested this client’s factory spatial configuration and began discussing a structural redesign.

The design emphasis is on "how to maximize productivity in a limited space." After ANKO engineers made careful calculations, they determined that at least 3 production lines were required to produce 100,000 Parathas per day. The original Paratha production line produces a 40cm wide dough sheet, which needed to be increased to a meter wide to be divided and fed into three production lines. A dividing conveyor belt is used to extend the dough sheet, separate the divided sheets, and connect each to the EA-100KA forming mold to further shape them into Paratha dough balls. After the dough balls are rested, they are passed to the PP-3 Automatic Filming and Pressing Machine to flatten the Paratha and stack them to complete the production process.

ANKO’s team has an in-depth understanding of mechanical equipment and food science, and this customized design is created based on professional experience and comprehensive technical capabilities. The “Triple Line High Capacity Paratha Production Line" is customized to reach a maximum capacity of 12,000 Parathas per hour, successfully meeting the client’s ultra-high production capacity requirements.

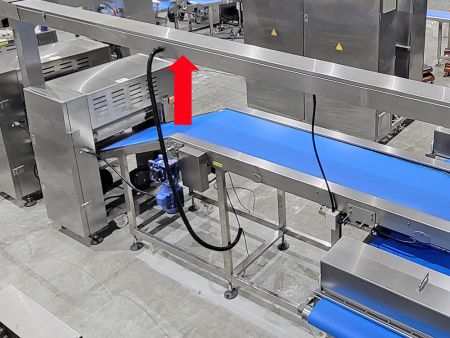

Solution 2. Providing a user-friendly machine configuration for safety concerns, ease of maintenance and operations

This “Triple Line High Capacity Paratha Production Line" is a large production line. In order to meet the customer's factory space, ANKO engineers placed the cream extruder on the left side of the production line and lowered the height of the machine to facilitate the input of cream. At the same time, based on the convenience of cleaning and safety considerations, after communicating with the customer, ANKO engineers arranged all wires above the machine and placed all motor inverters in the electrical box in the center of the production line. This move made maintenance and overall operations more convenient and more conducive based on centralization. In addition, in order to help the customer reduce labor requirements, the dough input that was overseen manually in the previous stage, is now equipped with a sensor that can automatically detect whether the dough needs to be added A bowl lifting and tilting machine can be configured for customers to significantly reduce manual feeding frequency.

Solution 3. Client food specifications: Paratha requiring sextuple layers than the original recipe

The customer's self-produced Parathas has only 6 layers, and they desire ANKO's assistance to increase the layers to 36. Therefore, our engineer adjusted the mechanism design and the number of layers of dough to be stacked, but the Paratha shrank. After an inspection, ANKO determined that the problem was with the temperature and time control of the dough, so appropriate adjustments were made... (contact ANKO immediately for more information)

ANKO continues to improve research on Paratha to gain a better understanding of local taste preferences, and continuously adjusts and optimizes manufacturing methods to respond to market demand. In the end, ANKO successfully produced 36-layer Paratha, weighing 65 grams and 80 grams, without the skin shrinking. After frying the Paratha until fragrant, the customer expressed great satisfaction with the texture and layers. This is a great example of a successful cooperation between ANKO’s Team and our customers.

ANKO has more than 46 years of professional experience in automated food production machinery. We are able to custom create Paratha made with desired layers, texture, oil content, etc., to create palatable products that are delicious and authentic. In this case, we successfully customized an exclusive Triple-line production equipment system for our clients, demonstrating our in-depth understanding of Paratha making and the use of sophisticated equipment.

Food Equipment Introduction

- Place flour and other ingredients in the ML mixer to form a dough.

- Place butter/ghee into the extruder.

- Place the premade dough onto the LP-3001M conveyor belt.

- Press ON to initiate the production process.

- The dough undergoes an automatic pressing and sheeting process

- The dough sheet automatically folds in the butter/ghee.

- An initial dough sheet layering is performed, then it’s pressed and sheeted.

- The process enters a second dough sheet layering, then pressed and sheeted again.

- The dough sheet is divided into three equal strips to be rolled up

- Each of the dough rolls enter the EA-100KA to be divided into individual dough balls.

- The dough balls are rested for around 30 minutes.

- The dough balls are placed in the PP-3 Filming and Pressing machine to be made into Paratha.

- Set the quantity of Paratha in a stack regarding to the client’s requirement.

ANKO Triple Line High Capacity Paratha Production Line is the leading automated equipment in the industry

The customized “Triple Line High Capacity Paratha Production Line" includes an automatic dough machine, dough sheeter, butter extruder, pressing device, forming machine, and a filming and pressing machine. All machines and devices are connected using the human-machine interface, controlled by the PLC program, which is the most important part of the automatic serial connection. Parameter settings and operating instructions can be easily set and controlled via a touch screen monitor; ANKO engineers will complete a series of parameter settings before shipment. After receiving the machine and assembling, clients can immediately start their production process.

- Solution Proposal

ANKO’s Customized Paratha Production Line: Designed to fulfill large Paratha orders

To meet the increasing market demand for Paratha in the marketplace, many manufacturers is using automated equipment to improve product quality and productivity. In Bangladesh, labor costs are relatively low, however, producing Paratha manually cannot meet the large market demand. Therefore, new automated production systems are quickly becoming the solution for local manufacturers. Automated machines can ensure the Paratha’s consistency in size, shape, layers, and greatly increases production efficiency.

In this case, ANKO included the ML series dough mixer, LP-3001M Paratha production line, EA-100KA forming machine and PP series fully automatic filming and pressing machine. ANKO can also configurate and provide Packaging machines, Weighing scales, X-ray inspection equipment, etc. to assist clients in building a customized Paratha production line to meet specific capacity needs and properly utilize factory space. For clients requiring smaller production and Paratha made with fewer layers, we recommend the SD-97 series Automatic Encrusting and Forming machines and the APB Pressing and Heating machine to perform a semi-automatic Paratha production line.

ANKO has partners in Bangladesh and India who can assist clients with utilizing local ingredients using our equipment to easily produce the most authentic Paratha. If you are interested in more details about ANKO machines and services, please click Learn More or fill out the inquiry form below, and we will get back to you shortly.

- Machines

-

ML Series

Preparing the dough is the first step for making Parathas. Using the ML dough mixer will speed up the mixing process. This series of Mixers come in 22- and 50-liter capacities and are recommended for small to medium-sized and also large food manufacturers.

LP-3001M

The LP-3001 provides two models - LP-3001L and LP-3001M. The difference is that LP-3001L only has one Z-shaped stacking mechanism and can only produce Parathas; while LP-3001M has two Z-shaped stacking mechanisms, allowing it to produce other products in addition to making Paratha. Since this client's needs ranged up to 36 levels, the customer ultimately purchased the LP-3001M model under ANKO's recommendation. This current production line can produce 40 to 130 grams of Parathas and is suitable for a variety of fillings. If the need is to increase the portion of fillings, the machine parameters can be reset. This machine is often used in conjunction with a fully automatic laminating and pressing machine.

EA-100KA

The EA-100KA is a Xiao Long Bao/Soup Dumpling forming machine that can process dough to make Stuffed Buns, Bao, and other spherical foods. This machine is often paired with the LP-3001 and HLT-700 series machines for producing Dumplings with flat edges, or with 9, or 12 pleats. The dough and filling ratio can be adjusted to meet different product specifications.

PP-3

To meet this client’s extremely high production output requirements, ANKO engineers designed a fully automatic Filming and Pressing Machine with 3 separate production lines and equipped each with a PP-3 Filming and Pressing Machine. It only requires placing the dough at the correct position on the PP-3, then the conveyor belt will automatically push the dough forward to be covered with film and flattened. After the film is slit and divided, the machine will automatically count and stack Parathas into a pile. The number of pieces in a pile can be adjusted, and an additional packaging equipment can be used.

- Country

Bangladesh

Bangladesh Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

Paratha is a common flatbread in Bangladesh and India; it can be enjoyed plain or filled with flavorful ingredients. Parathas are made with multiple layers, shaped into round, square, or triangles, and pan-fried until golden brown, fluffy, and crusty. This ANKO client is from Bangladesh, where Paratha is a food staple, especially for breakfast. Mughlai Paratha is a popular street snack in Bangladesh; filled with eggs, onions, green chilies, and cilantro, it is often served at lunch or as a side dish for dinner.

Manu local food manufacturers sensed the tremendous flatbread business opportunity and begun to manufacture and package frozen Plain Paratha, Aloo Paratha, Keema Paratha, and Deshi Paratha, selling them in major retail stores and supermarkets. Additionally, some manufacturers have launched Parathas that are made with low-fat recipes, or with all natural ingredients targeting health-conscious consumers.- Handmade Recipe

-

Food Ingredient

Flour, salt, sugar, water, ghee/shortening

How to make

(1) Mix flour, salt, and sugar in a bowl. (2) Add hot water into the flour mix and knead it into a dough, then let it rest for 20min. (3) Sprinkle some flour on the work surface before kneading the dough to prevent the dough from sticking. (4) Shape the dough and roll out into a flat sheet. Spread a thin layer of ghee on the dough sheet then sprinkle some flour on top. (5) Roll the dough sheet up, and then divide into small dough balls. (6) Use the rolling pin to flatten the dough balls into Parathas. (7) Place the flattened Parathas onto a heated frying pan, brush the pastry with oil or ghee and pan fry till golden brown.

- Downloads

English

English